Other inspection systems

Other inspection systems

Three-piece can in-line inner surface inspection systemMulti-gathering inspection systemSaddle stitching error inspection system

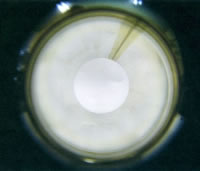

Three-piece can in-line inner surface inspection system

(System for inspecting indentations, dirt, and body weld spatter, etc. in-line in a can-making line)

The basic concept of GICS, the efficient in-line inspection technology, can be applied not only to the inspection of printing processes, but also to the in-line inspection of various post-processing processes.

- 3-piece can in-line inside surface inspection system Basic specifications

- Inspection speed (touch screen operation)

- Up to 450 cans per minute

- Resolution

- 0.2mm×0.2mm

- Plate type

- Tinplate aluminum plate

- Body size

- Height 100 mm

- Test surface

- Single-sided specification

- Control panel

- wide700 mm × high 500 mm × depth400 mm

- Power capacity

- Single phaseAC 200 V 2.2 KVA

- Operation panel (separate)

- 21.5 inches (touch screen operation)

Multi-gathering inspection system

Usually, a heterogeneous inspection system, such as a random signage inspection system, checks whether there are any different types of images in comparison with a single master image (reference image). In Jix's Multi-Joint Inspection System, however, a large number of different combination groups are inspected as master images.

For example, a set of multiple sheets of different images, such as a calendar or playing card.

You can check whether there are different sheets in them, and whether they are in the wrong order.For example, a set of multiple sheets of different images, such as a calendar or playing card.

You can check whether there are different sheets in them, and whether they are in the wrong order.

- You can check whether there are different sheets in them, and whether they are in the wrong order.

- Maximum number of combined

- 250 sheets

- Inspection speed

- Up to 10,000 sheets/hour

- Resolution

- 0.1 mm×0.1mm

- Inspection method

- Pattern matching of the specified image of the sheet

- Camera

- Color CCD camera

- Seat following range

- Up, down, left and right plus or minus 5 mm

- Control panel

- wide700 mm × high500 mm × depth 400 mm

- Power capacity

- Single phaseAC 100 V 1.5 KVA

- Operation panel (separate)

- 21.5 inches (touch screen operation)

Saddle stitching error inspection system

A system for checking stitching errors in a saddle stitcher.

A specially developed inspection algorithm and lighting system can determine an inside stitch error from the external shape of the stitch.

- saddle stitching error inspection system Basic specifications

- Machine speed

- Up to 12,000 sheets/hour

- Stitch rate

- Maximum of 4 locations (for two-story bookbinding)

- Resolution

- 0.1 mm×0.1mm

- Inspection method

- Pattern matching of stitch image

- Camera

- Color CCD camera

- Correspondable wire material

- Iron-copper

- Control panel

- wide700 mm × high500 mm × depth400 mm

- Power capacity

- Single phaseAC 100 V 1.5 KVA

- Operation panel (separate)

- 21.5 inches (touch screen operation)

-

Information on business and recruitment is provided.

-

Explain Jix products