Variable Image & Data Inspection Feedback System

TheoryPatented material

Variable Image & Data Inspection Feedback System

TheoryPatented material

Variable Image & Data Inspection Feedback System Theory

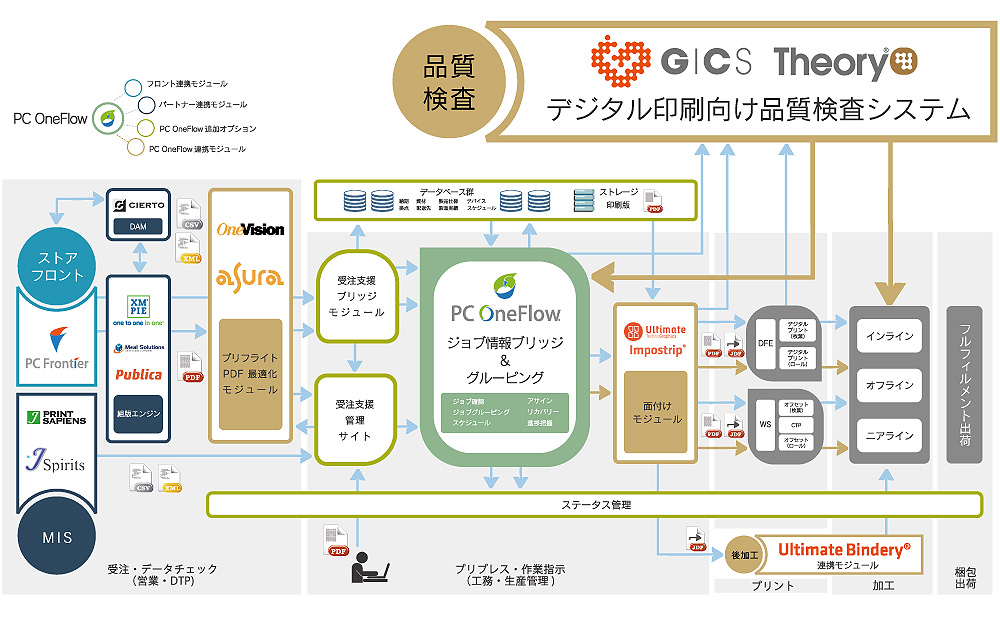

A quality inspection system for digital printing that fully covers the quality assurance needs of future digital printing, as well as realizing the printing paper inspection function of the Lab-vision print quality inspection system for variable images peculiar to PODs.

Inspection equipment for sheet-fed digital printing machines Theory sheet

Inspection apparatus for rotation digital printing machine Theory web

Characteristics of the Theory

- Theory <Theory> of quality testing systems for digital printing that cover all quality assurance needs in digital printing

- Theory® is an inspection device for digital printers that can inspect the entire

surface of variable printed graphics and simultaneously inspect variable data such as serial

numbers and bar codes.

You can scan(Theory-sheet) up to 100 sheets of B2 size per minute , check the print quality, and read variable information such as OCR and bar code decoding.※Theory-web(~300m/min) - Print quality inspection of variable images

- The quality of printing is checked using digital plate-making data, such as PDF, as a master, Different plate-making data are replaced for each printing unit of the same pattern, and for each sheet, each sheet is replaced for each sheet, and the inspection is performed by comparing the printed copy with the plate-making data.

- Variable data reading function

- The Theory® can read a number of serial numbers, bar codes, etc. printed on the pages, check the read data, and record which prints are faulty if there are print-quality problems, and record lists of recovery productions (reprints).

- Defect detection data output

- The quality of the printed design, the error of the variable data, or both of the

detected sheets (or pages or faces) are recorded as a problem, and can be output to the data

sheet to be fed back to the upstream side of the digital workflow.

Also, by outputting the inspection history data sheet to the downstream side in the same manner, it can be used as inspection information for sorting such as discharge in the post-process.

- Theory-sheet 330 (A3 Novi) Basic Specifications

- Maximum paper size (mm)

- Width 330 × length 485

- Minimum paper size (mm)

- Width 100 × length 148

- Paper thickness

- 75g/m²~550g/m²

- Maximum speed (sheets/minute)

- 100 sheets per minute (A3 size)

- Scan resolution (mm)

- Width 0.1 × Length 0.1

- Corresponding variable data

- 1. JAN/EAN 2. code128 3. code39 4.NW-7(codabar) 5.ITF 6.QRcode

- Corresponding serial number

- OCR-B

- Minimum Resolution of Imaging Examination (mm)

- Width 0.1 × Length 0.1

- Feeder and Stacker Effective Paper Loading

- 500mm

- Feeder method (*Offline option)

- Top feeder system using soccer heads

- Reject stacker (optional)

- ○

- Dual Feeder (optional)

- ○

- Power supply

- Three-phase AC200V 30A

- Weight (excluding options)

- 150KG

- Air source

- 0.5 MPA 40 L per minute

- Outer dimensions (mm)

- W3050×H1400×D700

- Theory-sheet 530 (B2) Basic Specifications

- Maximum paper size (mm)

- Width 530 × length 750

- Minimum paper size (mm)

- Width 128 x length 182

- Paper thickness

- 75g/m²~550g/m²

- Maximum speed (sheets/minute)

- 100 sheets per minute (B2 size)

- Scan resolution (mm)

- Width 0.13 × length 0.13

- Corresponding variable data

- 1. JAN/EAN 2. code128 3. code39 4.NW-7(codabar) 5.ITF 6.QRcode

- Corresponding serial number

- OCR-B

- Minimum Resolution of Imaging Examination (mm)

- Width 0.13 × length 0.13

- Feeder and Stacker Effective Paper Loading

- 500mm

- Feeder method (*Offline option)

- Top feeder system using soccer heads

- Reject stacker (optional)

- ○

- Dual Feeder (optional)

- ○

- Power supply

- Three-phase AC200V 30A

- Weight (excluding options)

- 200KG

- Air source

- 0.5 MPA 40 L per minute

- Outer dimensions (mm)

- W4000×H1600×D850

- Theory web (rotary type)

- Maximum paper size (mm)

- Width 1100

- Minimum paper size (mm)

- Width 530

- Paper thickness

- Depend on the printing press

- Maximum speed (sheets/minute)

- MAX 300 m/min

- Scan resolution (mm)

- Width 0.13 × length 0.27

- Corresponding variable data

- 1. JAN/EAN 2. code128 3. code39 4.NW-7(codabar) 5.ITF 6.QRcade

- Corresponding serial number

- OCR-B

- Minimum Resolution of Imaging Examination (mm)

- Width 0.13 × length 0.27

- Feeder and Stacker Effective Paper Loading

- ─

- Feeder method (*Offline option)

- ─

- Reject stacker (optional)

- (Data-output)

- Dual Feeder (optional)

- ─

- Power supply

- Three-phase AC200V 30A

- Weight (excluding options)

- ─

- Air source

- ─

- Outer dimensions (mm)

- ─

-

Information on business and recruitment is provided.

-

Explain GICS products